Failure of critical assets has significant financial, legal and safety implications

And creates economic challenges for asset-intensive businesses and the customers they serve

In today’s environment, asset-intensive industries such as utilities, mining companies, railways and more, face many challenges: aging assets, stagnant budgets, new operating risks and a workforce in transition. Luckily, advances in predictive and prescriptive analytics offer new capabilities to help meet the expectations of high reliability in spite of these challenges.

Hitachi APM is designed to provide health and performance insights to prevent critical asset failures while optimizing asset lifecycle costs.

The solution enables companies to leverage their online and offline data to drive more intelligent, risk-based approaches to asset management in alignment with industry standards such as ISO 55000 and PAS 55.

As a proven leader in both electrical systems engineering and asset management process innovation, Hitachi Energy is ready to support your transformation to smarter asset performance management. Available on premises or via the cloud, Hitachi APM combines Hitachi Energy’s unparalleled technical expertise with collaborative asset performance management workflows on a world-class, secure and extendible analytics platform.

Hitachi APM is an essential solution that enables asset-intensive organizations to:

- Manage asset health cost-effectively

- Effectively address identified risks

- Prioritize repair and replace decisions

- Know “when + what if”: the next level in prognostics

Get the bigger picture from the myriad sources of asset data available today and know where to focus your in-depth engineering analysis and scarce field resources. Hitachi APM collects your data via standard and secure interfaces, and Hitachi Energy’s embedded asset models help interpret the available data to provide new insights.

Get the bigger picture from the myriad sources of asset data available today and know where to focus your in-depth engineering analysis and scarce field resources. Hitachi APM collects your data via standard and secure interfaces, and Hitachi Energy’s embedded asset models help interpret the available data to provide new insights.

Hitachi APM supports an engineering evaluation workflow, including notification of key new information, visualization of core data by asset type, equipment assessment documentation to add context to the data, and initiation and tracking of work in common enterprise asset management (EAM) systems. In addition to the embedded Hitachi Energy models, Hitachi APM’s Open Model Interface (OMI) enables partners, customers and other providers to add additional asset models and leverage machine learning.

Early identification of changing and degrading conditions is only the first step in an effective asset performance management program. Hitachi APM’s issue tracking ensures that identified risks are reliably mitigated and resolved. The solution highlights key actions that are at risk and tracks the completion of the important actions in the EAM system. It also provides tools for resolving identified risks before they materialize.

In addition to resolving issues identified through predictive asset analytics, companies have much more to accomplish on a daily basis, such as regulatory inspections and maintenance. There is often more work in the backlog than resources to complete it. How do you decide where to start in order to have the most significant impact on overall risk? Though a maintenance prioritization algorithm, Hitachi APM provides a suggested order that enables a risk-optimized maintenance schedule.

With limited capital budgets, companies also must make choices related to long-term spending:

- Considering all pertinent factors, which projects provide the greatest risk reduction?

- Which aging equipment effects can be mitigated more costeffectively?

- Can additional capital expenditures be justified to the regulator or other stakeholders?

The core building blocks of Hitachi APM, which include a replacement priority algorithm, lay the foundation to help answer questions like these and support better decision making in the capital planning process.

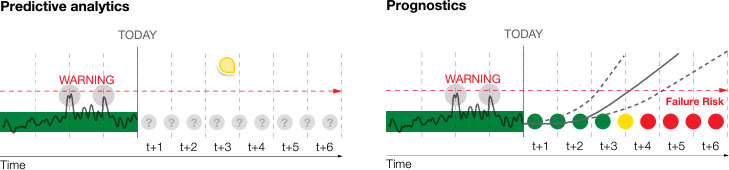

Next-level prognostics and scenario simulations provide the knowledge of “when” and “what if.” By helping companies to better understand the trade-offs and impacts of different possible scenarios, Hitachi APM can improve decision-making and operations planning.

This field-proven technology accurately predicted 99% of equipment malfunctions with a time horizon of as much as five years, and the solution’s accuracy continues to increase over time through its data-driven machine learning capabilities.

Armed with knowledge of when the risk of asset failure will reach a critical level, users will be able to optimize their corrective action schedule, based on market condition forecasts or leveraging pre-scheduled outage windows for example. Simulation experiments such as, “How much can the forecast asset failure risk acceleration be postponed by reducing load to 90%?” help users evaluate alternative scenarios for optimal decision making.

- Is our asset still functional?

- Are all parameters in the normal range?

- Are alert and alarm thresholds set correctly?

- Do we observe the right parameters?

- What condition does our asset have?

- Why is this asset condition critical?

- Where is the source of the problem?

- How could we resolve the problem?

- When will we reach a critical condition?

- When can we expect a malfunction or failure?

- When will we get an alert or alarm?

- What happens if we take a particular action?

Monitoring

- Is our asset still functional?

- Are all parameters in the normal range?

- Are alert and alarm thresholds set correctly?

- Do we observe the right parameters?

Diagnostics

- What condition does our asset have?

- Why is this asset condition critical?

- Where is the source of the problem?

- How could we resolve the problem?

Next-Level Prognostics

- When will we reach a critical condition?

- When can we expect a malfunction or failure?

- When will we get an alert or alarm?

- What happens if we take a particular action?

Putting it all together

In a collaborative environment and modular architecture for effective change management.

Leading analysts recommend that the most effective adjustment for achieving financially optimized asset management starts with a focused scope (one asset type, one facility, etc.) and scales to benefit the entire fleet with prioritization across asset types, locations and other classifications. As an example, Hitachi APM currently supports over one million assets including transformers, circuit breakers and station batteries in a single instance at a leading United States utility delivering power to customers across 13 states.

Hitachi APM’s scalable architecture allows new users to be up and running within hours to support quick returns on effort and low-risk pilots. The application meets core IT requirements such as cyber security, single sign-on and standardized integration to common third-party systems. It is also extendible so that analytics can evolve with the maturity of your asset management program. Extensions may be added by the user and maintained with commonly-available skillsets or with your existing reporting tools, avoiding the need for specialized platform training.

An Essential Part of your Business.

The benefits of asset performance management are well documented:

- Increased reliability by identifying, prioritizing and resolving risks before they materialize

- Lower maintenance costs by reducing ineffective time based practices and expensive failures

- Lower capital expenditures by getting longer economical life out of existing assets

- Structured knowledge capture that facilitates job transitions

- More efficient compliance management through lean workflows and embedded reporting

Better still, Hitachi APM is the most proven and efficient asset performance management solution available on the market. Its speed of implementation and extendibility allows you to start lean, experiment and learn, and accelerate your organization’s digital transition while savings are materialized.

Asset & work management, powered by Hitachi

More than a system. An ecosystem.

APM is designed to provide health and performance insights to prevent critical asset failures while optimizing asset lifecycle costs. Leverage online and offline data to drive more intelligent, risk-based approaches to asset management.

EAM delivers business outcomes at a sustainable and superior cost of operations and capital investment. EAM instills best practices and processes to help you manage assets from day to day and throughout their lifecycle.

FSM is a highly scalable and intuitive inspection, maintenance, and repair application. Designed for asset-intensive environments like substations, FSM equips mobile users to execute work orders in the field with optimal efficiency.

APM is part of the Hitachi portfolio for asset & work management, software that enables asset-intensive industries to be more adaptive, collaborative, insightful and predictive. More than a system, it’s an ecosystem that embraces your existing technologies, enabling you to gain the benefits of the latest technological advances without sacrificing the investments you have already made.

The Hitachi software portfolio offers the latest in development and delivery paradigms, with a modular architecture that is designed to support customer needs for agile delivery in a changing market. Customers can deploy precisely what is needed, when it is needed—this “selective consumption” model liberates customers from the forced “rip & replace” upgrades of the past.

These solutions are interoperable with our customers’ investments in other complementary solutions. For maximum flexibility and choice, Hitachi solutions are available via the cloud or on premises.

1Value model validation by Deloitte; no endorsement is expressed or implied. Upfront buy-in of ~$4.5M yields $7.8M in value in year 1.

2Hitachi APM examples of customer-demonstrated and validated first year savings for AEP relative to work prioritization, prevention of asset failure and improved work.

3These are first-year savings. For five years, the cumulative savings are roughly $71M for the first phase of assets (transformers, circuit breakers, batteries)