To achieve success in this endeavor, it’s crucial to deploy these technologies with a strategic and informed approach. By doing so, we can not only facilitate seamless interaction among stakeholders but also drive substantial cost reductions, enhance safety protocols and elevate operational efficiency. This can directly bolster financial performance and also fortify our long-term competitive edge and sustainability.

The natural gas industry must prioritize achieving digital maturity to meet global demand for reduced carbon emissions. According to the U.S. Energy Information Administration, natural gas generated 0.97 pounds per kilowatt hour of CO2 emissions in 2021. Conversely, coal generated 2.26 pounds of CO2 emissions per kilowatt hour that same year1.

AI and data science can help uncover valuable insights for improving marketing strategies in coal-dependent foreign markets.

This white paper will enhance your understanding of AI-powered asset performance management. It will explore the application of AI and data science capabilities within the natural gas sector. You’ll learn how the right data partner and solution can help you answer the demands of stakeholders with diverse interests, improving operational efficiency and enhancing asset, labor, resource and cost control. You’ll also discover how an intelligent asset management solution can accelerate decarbonization, optimize production to capitalize on domestic and global market opportunities, and reduce emissions.

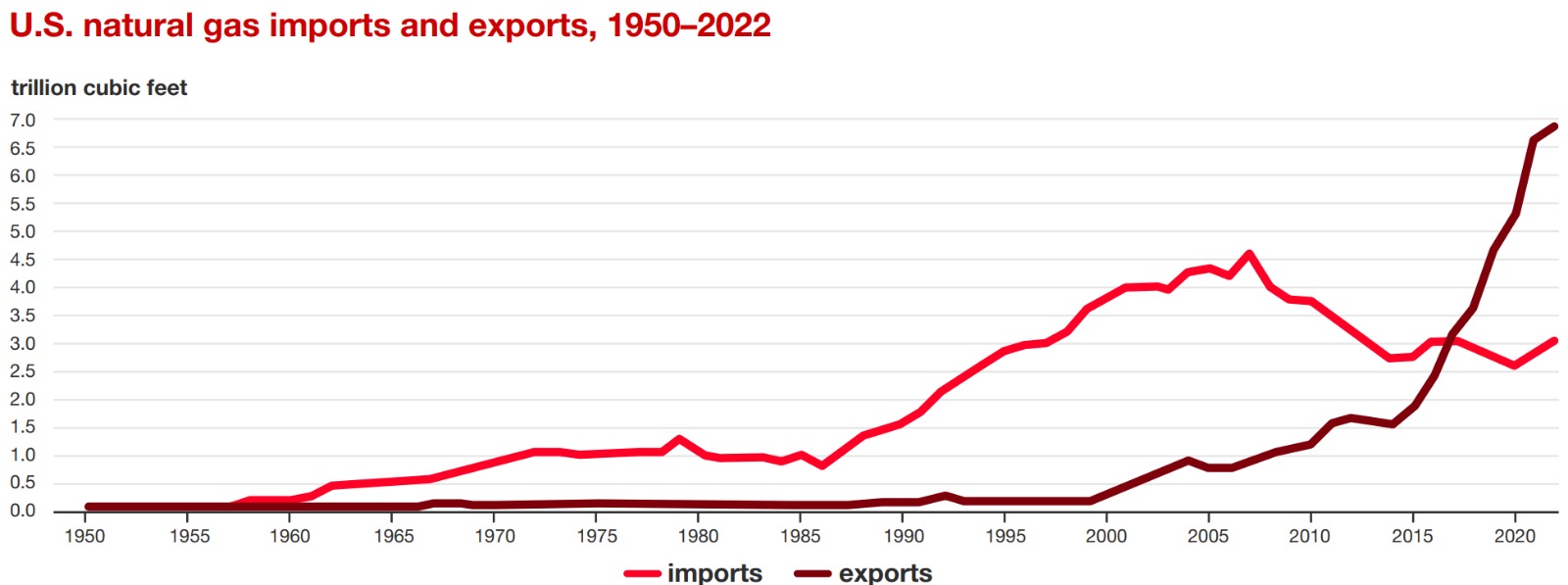

Data source: U.S. Energy Information Administration, Natural Gas Monthly, April 2023; data for 2022 are preliminary

The natural gas industry functions in a complex ecosystem of diverse owners, equipment makers, service providers and operators. Motivated by distinct and often competing economic, operational, environmental and accountability priorities, these stakeholders face five major challenges that Hitachi Asset Analytics can address.

Natural gas field operations are often based in remote locations that experience extreme environmental conditions, including severe heat or cold, dust, corrosive elements and disruptive weather events. Machinery and equipment, including highly specialized compressors and pumps, are expected to operate seamlessly. However, these harsh environmental elements pose challenges. When machinery malfunctions or fails, the remote location and the scarcity of repair and maintenance experts can bring production to a standstill. While remote asset fleet monitoring tools can identify warning signs before malfunctions occur, they cannot facilitate proactive solutions on their own.

But Hitachi Asset Analytics can, with expert data monitoring tools that identify anomalies ahead of time to enable predictive maintenance. The solution can provide analytics-backed decision support to help determine equipment ownership and cost responsibility. And to maximize OPEX spend, Hitachi Asset Analytics can be used to analyze how mechanical availability compares to actual utilization.

Remote asset installment and operations require longer planning and greater attention to detail. And there’s always the risk of unforeseen system breakdowns that could leave the operations team without essential equipment. The minimal instrumentation on these remote assets further complicates operations planning — especially for truck rolls, which may be initiated by maintenance personnel lacking a thorough understanding of the on-the-ground asset condition. In some cases, the result has been for equipment to be changed prematurely, before the end of its useful life.

Hitachi Asset Analytics provides intelligent asset management through clear condition and similarity mapping using algorithms. The system has a 93% accuracy rate in predicting next-day failures, next status and next status time-of-occurrence, and duration. By predicting the failure class and associated subsystem, it affords service providers and operators critical support in effective planning. It also minimizes the operational emissions associated with truck rolls and reductions. And finally, it has been found to reduce non-productive time (NPT) and help to refocus human effort and cost.

Assets within a given operation may include different technology generations, different levels of technical maturity and tools that are not designed to communicate seamlessly with one another. Original equipment manufacturers (OEMs) may use proprietary or customized technologies that likewise are not designed to promote interoperability with other systems. The result is a complicated mix of legacy and modern technology from multiple OEMs operating together on field assets.

Productivity in such an ecosystem demands expertise in preprocessing and system operation. This approach is extremely laborious — and even when subject matter experts are managing the process, the information may be logged improperly. Furthermore, specialized setup and model training are required for every new asset in the network. To simplify the process of asset configuration and meta information management and tracking, Hitachi Asset Analytics integrates requirement-based asset tagging and multi-scale lookup for performance tracking. The solution also delivers basic filtering and complex manipulation capability on the GIS lookup. Its capabilities encompass mapping of interactivity options and hypothesis analysis, in addition to predictive analytics.

Natural gas compression industry service providers must confront challenges in operational efficiency that originate in equipment-centric management. Stacked or delayed signals prevent providers from accessing asset data in a timely manner. Additional challenges arise due to operational inefficiencies caused by multiple systems without context for the process and ecosystem.

Hitachi Asset Analytics is a scalable, highly dependable solution that is easy to integrate with existing IT systems. To help bridge the data gaps that come with remote equipment operations — and to help lower incongruence in data setups and uncertainty in availability — it features:

The natural gas value chain encompasses owners, equipment makers, service providers and operators, each with their own priorities. These contrasting — and often conflicting — interests make it difficult for stakeholders to track, monitor and assess key benchmarks.

Hitachi Asset Analytics helps resolve competition and conflict in pursuit of these goals by delivering key performance indicators (KPIs) and key resource indicators (KRIs) that are tailored to a wide range of stakeholder groups. This simplifies and harmonizes business and process complexities to promote efficient tracking and reporting, and ensure accountability across the board. It boosts efficiencies and profitability through the use of advanced, reliable, and proven data science-based machine and asset analytics.

Operators are being held accountable for their CO2 emissions and the results from programs they’ve undertaken to reduce their carbon footprints. This includes the Global Methane Pledge, which calls for organizations to collectively reduce methane emissions by a minimum of 30% below 2020 levels by 20302. As an outgrowth of this shift in social and regulatory expectations, corporations in the sector are starting to question the wisdom of paying for the mechanical availability of equipment as opposed to utilization.

Hitachi Asset Analytics allows stakeholders to balance high mechanical availability and optimal utilization by analyzing both factors. In addition to ensuring cost-effectiveness and productivity, this helps organizations meet sustainability targets and reduce greenhouse gas emissions.

Designed to answer the demands of stakeholders with divergent interests, Hitachi Asset Analytics streamlines complex operations, directing users towards practical strategies for improved efficiency. Its features and capabilities include:

These capabilities translate to a broad spectrum of outcomes and benefits that enhance overall performance, unlock growth potential and deliver a return on investment for all stakeholders. Results of implementing the solution include:

Maximization of labor efficiency and minimization of labor expenditures via an AI/ML-based predictive solution in line with remote operational schedules, which facilitates remote asset analytics and maintenance over an open-loop system in a tightly controlled environment.

A failure prediction model enables accurate truck rolls, and field fleet services may be optimized to ensure personnel are deployed to the right place at the right time.

Channelized views and remote configuration management for high-tech assets enable achievement of and reporting on KPIs and KRIs tailored to the priorities and values of diverse stakeholder groups.

Cost insights are delivered with complete interactive and drill-down charts.

Hitachi Asset Analytics delivers AI-powered asset performance management that converts reactive operations into a predictive engagement system. Our asset clustering solutions give operators decisionmaking insights and facilitate model portability. We also support the elimination of data uncertainty by creating a highly dependable event-based analytical framework.

When you partner with us, you draw on the asset intelligence record and industry-tested expertise of one of the world’s largest energy companies, with $14 billion in energy revenue and more than $4 trillion in assets under management globally. With a track record of improving customer value and ensuring safe and secure operations, our solutions drive your digital transformation, save on operational costs, reduce risks and secure operations.

Service providers for the natural gas industry face operational inefficiencies caused by diverse stakeholder groups and multiple, disparate systems. With an event-driven analytics framework, inputs from multiple components and OEMs can be captured and analyzed in the same framework. The resulting drill down charts declutter the system, enabling operations teams to plan for appropriate maintenance activity instead of reworking or replacing the entire system. In addition, stakeholder-centric apps provide actionable insights based on the functional contributions of each stakeholder.

Hitachi Asset Analytics aggregates data collected from multiple subsystems to deliver a complete solution that relies on data-driven algorithms. This allows data collected from natural gas compressor f leets to be analyzed, and the insights derived from this approach can facilitate detection and prediction of compressor shutdowns, as well as reduce mean downtime. Using high-level process modeling and dependability metrics, Hitachi Asset Analytics creates models that capture interactions between the process and the equipment to reduce inefficiency costs. The solution has been shown to improve overall operating efficiencies in the field by 30%.

Hitachi Asset Analytics offers numerous advantages, including:

Improved asset control and management.

Enhanced labor efficiency and reduced expenditures.

Lowered emissions and increased decarbonization efforts.

Optimized production and reporting on key performance indicators.

Real-time cost control with interactive charts.

About how working with Hitachi can produce asset insights that convert your gas collection into a data-driven science of competitive performance.

1U.S. Energy Information Administration, Frequently Asked Questions, November 25, 2022, https://www.eia.gov/tools/faqs/faq.php?id=74&t=11

2Climate & Clean Air Coalition, “Global Methane Pledge,” Globalmethanepledge.org, https://www.iea.org/reports/global-methane-tracker-2022/the-global-methane-pledge

By subscribing to Hitachi Digital Services’ Insights and providing your e-mail, you agree and consent to Hitachi Digital Services´ Privacy Policy and Website Terms of Use. Data Controller: Hitachi Digital Services Corporation. Purpose: manage Hitachi Digital Services.

Read More +